File:

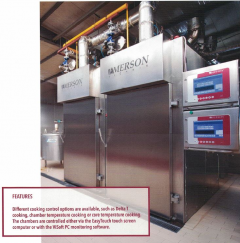

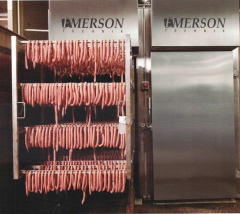

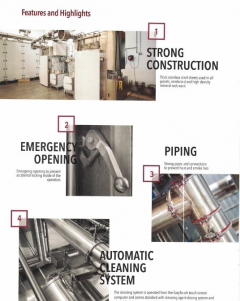

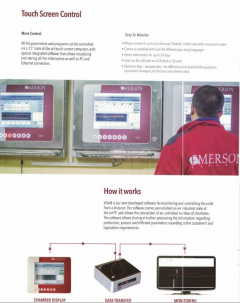

The Emerson-Technik GmbH and cooking units are allowing automatic heat treatments for meat, fish or other food products. In order to guarantee the uniformity of the products, our chambers use one fan for each trolley and one extra evacuation ventilator. The perfect coordination of the sizes and parameters results in shorter programs and improved yields, thanks to the reduced loss. Our customers can choose from saw-dust, wood chips or liquid smoke generators depending on their facilities and the desired products. The modular construction from high quality stainless steel and mineral rock wool panels allows our chamber to be installed in different locations, from small to mid-sized to high capacity factories. All the Emerson-Technik GmbH smoking and cooking chambers are coming standard with an automatic cleaning system, cleaning agent dosing and with water pressure pump (optional). The chambers are controlled either via the EasyTouch touch screen computer or with the ViSoft PC monitoring software. Extra optional benefits include showering, cold smoke option, horizontal air flow, automatic door opening, extra rear door/s or catalytic afterburner.

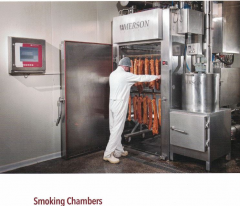

Fish Smoking Chambers

Our customers can choose from saw-dust, wood chips, friction or liquid smoke generators depending on their facilities and the desired products. The air flow can be vertical or horizontal for fish laying on nets. the heating can be either steam, gas, LPG, diesel, oil or electric, each system ensuring the reach of the desired parameters in optimal time.

Benefits:

Reliability due to strong materials and processes

Weight loss reduced to minimum

Less energy consumption due to innovative airflow design

Fast programs thanks to the design of the ventilating system

Uniform products

Complete control over the processes due to touch-screens

Emerson-Technik provides customers with additional features such as: chambers, showering, cold smoke, horizontal air flow, automatic door opening, extra rear door/s or catalytic afterburner.

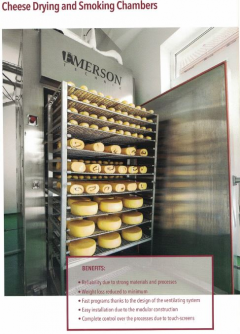

Cheese Drying and Smoking Chambers

For smoked cheese application, Emerson-Technik GmbH smoking chambers usually use the cold smoke system. The perfect air circulation, together with the low smoke temperature (controlled by the cooling register) ensure that the product will have less loss after the drying - smoking process and also a perfect maturation.

Benefits:

Reliability due to strong materials and processes

Weight loss reduced to minimum

Fast programs thanks to the design of the ventilating system

Easy installation due to the modular construction

Complete control over the processes due to touch-screens

The chamber is designed to have optional horizontal air circulation for laying products on the grates. Thanks to the horizontal air circulation, the trolleys can be constructed with many levels and the capacity will be increased. Also, the heating can be adjusted for maturation and humidity control. Our customers are welcome to choose from saw-dust, wood chips, friction or liquid smoke generators.